Design and verification

Platforms

- Processors- ARM, X86, Tensilica, Microblaze, Picoblaze

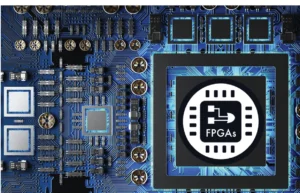

- Boards- Altera, xilinx based multi-FPGA boards

- Emulators – Zebu, Veloce & Palladium

Interfaces

- AXI, AHB, APB, PLB

- PCIE, SATA, DDR

- MAC, USB

- SDIO

- MIPI – DSI, MIPI- CSI

- WLAN 802.11 a/b/p/g

- H264 Decoders

- CAN , I2C, SPI, UART

- DMA, CRYPTO, PRNG

Tools

- Synthesis Tools – Xilinx Vivado, Xilinx ISE, Altera Quartus, Mentor Precision, Cadence Quiclturn

- Partition Tools – Synopsis Certify

- Simulation- Modelsim, Questasim, Cadence NCSim & Quickturn

- System Debug – ARM realview ICE, Xilinx chipscope, Altera signaltap, Synopsis Identify, Debussy, J-Link, Trace-32